Wexus' Pump Health Monitor feature allows you to remotely track your irrigation pump efficiency and get alerted in real time in the field before problems get worse.

How does it work?

- Know which irrigation pumps across your farm are wasting money and energy, and where to take action.

- Remotely tracks pump efficiency rating on a daily or monthly basis via a utility electric meter (or installed energy monitoring device) and water flow meter (installed, connected via your water vendor's API, or from estimated usage).

- Alerts growers to pumps that need maintenance, pumps that are at risk of failure, and dropping well water levels.

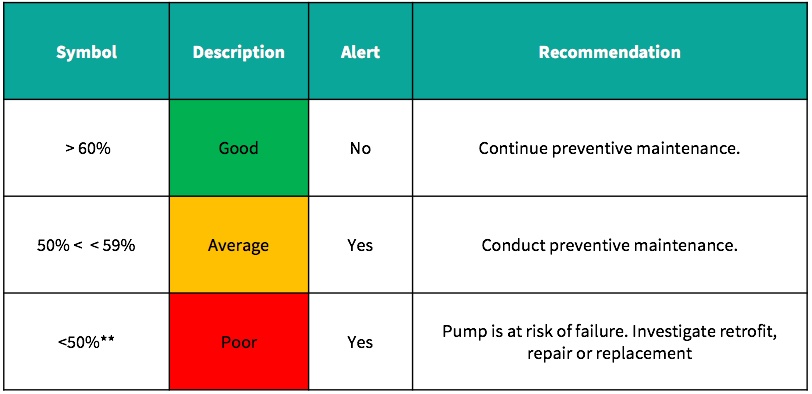

What does the pump efficiency percentage mean?

Pump Performance Efficiency Scale. Based on Advanced Pumping Efficiency Program guidelines. (**Efficiency less than 5% could indicate that a pump is not operating.)

Pump Performance Efficiency Scale. Based on Advanced Pumping Efficiency Program guidelines. (**Efficiency less than 5% could indicate that a pump is not operating.)What drives irrigation pump health?

- Efficiency: The product of the motor efficiency and efficiency of the pump. The units are represented in percentage (%).

- Energy Consumption: Measured in 15 minute intervals in units of kilowatt-hours (kWh).

- Water Consumption: The total amount of water that flowed through the pump for a specific time period. The units are represented in gallons (gal), acre-feet (AF) or acre-inches (AI).

- Flow: The amount of fluid flowing through the pump while running. The units are represented in gallons per minute (GPM), or acre-feet/acre-inches per minute (AF/AI-m).

- Depth: The total height that the water must be lifted to reach the pump and ultimately the crop.

- Cost per Acre-Foot ($/AF): The real cost of irrigation. Measures the actual energy costs required to move an acre-foot of water either out of the ground or over the ground surface.

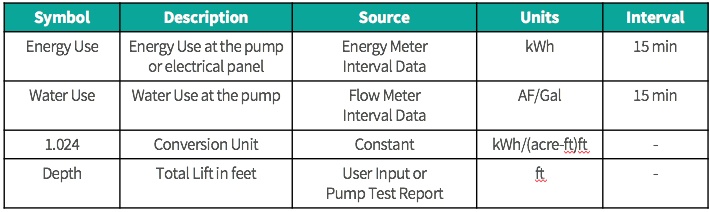

How do you calculate irrigation pump efficiency?

- Via an industry-standard equation based on fundamentals of mechanical engineering:

Pump Efficiency = (Water Use * Depth * 1.024) / Energy Use

Variables entered into the pump efficiency equation.'

Variables entered into the pump efficiency equation.'

Are you leaving money & energy on the table?

Avoid pump or well failure with proactive energy management. Wexus' real-time insights can alert you before equipment or well failure and potential crop loss.

Here are some real world examples of the benefit of tracking pump efficiency via Wexus' platform.

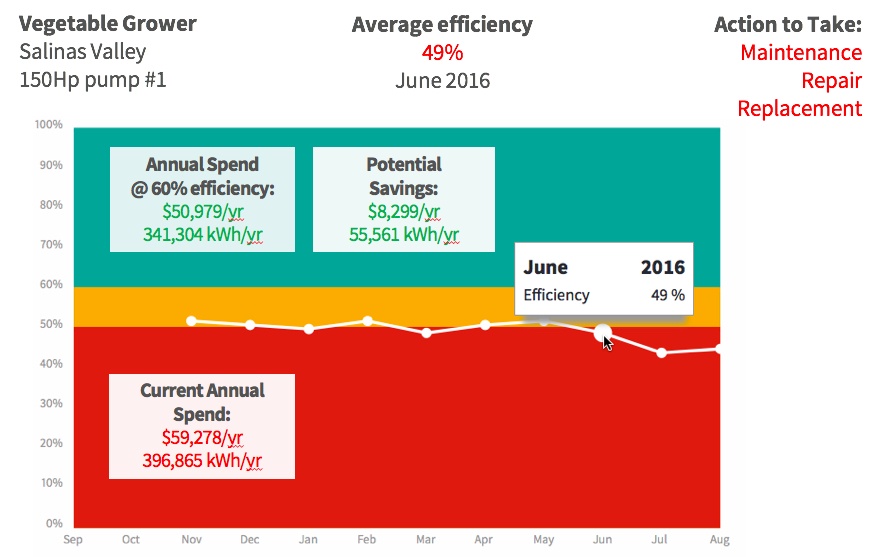

Vegetable Grower, Salinas Valley CA, Dropping pump efficiency

Wexus identified +$8,000 in cost savings & +55,000 kilowatt-hours (kWh) in energy savings for 1 irrigation pump.

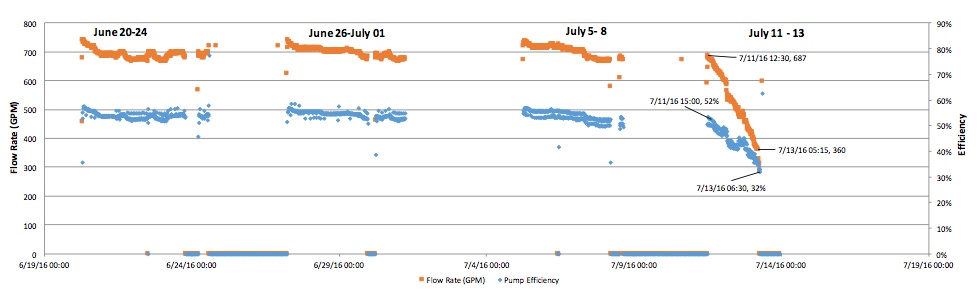

Vineyard, Salinas Valley CA, Pump failure due to well blowout

Wexus measured significant decreases in pump efficiency 2 days before a well pump failed. This was caused by a blowout on a 20 year old well, which burned out the pump motor.

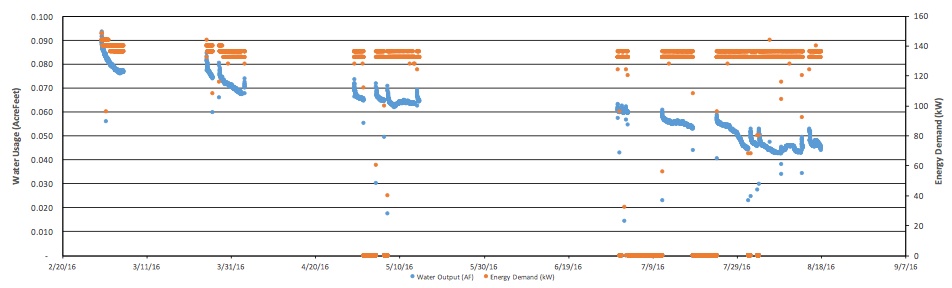

Dairy & Alfalfa Grower, Central Valley CA, Dropping pump efficiency due to falling well water levels

Wexus measured significant decreases in water output, high energy usage, and dropping efficiency over several months on a well that had recently been re-drilled to deeper levels. This was caused by falling aquifer levels & the well potentially running out of water.

What are the root causes of pump problems?

Common Causes of Wasted Energy:

- Lack of system maintenance.

- The wrong pump for the system.

- Pump wear from cavitation or abrasion.

- Improperly sized or designed fittings.

- Water source changes. Falling aquifer levels.

How to Improve Pump Energy Efficiency (for Electric Motors):

- Rebuild older motors & gain several % points in motor efficiency.

- Consider a premium-efficiency motor over a standard-efficiency motor when installing a new system, when replacing over or undersized motors, or when the cost of rewinding exceeds 65% of the price of a new motor.

- Consider a variable frequency drive (VFD) if you need to produce a wide range of flows & pressures to meet varying system needs.

- Constant-pressure valves or flow-control nozzles may be a lower-cost alternative to a VFD, (although they’re less energy efficient).

- For more Wexus training, updates, case studies and product tutorials check out our blog page here.

- For more information about how Wexus can drive energy and water efficiency, automation and cost savings check out our home page here where you can schedule a demo of our software platform or sign up for a free proposal.

- Be sure to follow us for the latest updates and news on Twitter, LinkedIn and YouTube.